Engine Dyno Testing

Engines are a major strength at Denis Welch Motorsport. For 30 years we have developed an array of specialist parts to enhance performance. To evaluate the increasing power we develop from our race engines requires a controlled and safe environment in which to measure engine performance according to variables.

When we started to out-grow the power bands of our 20 year old dynamometer, we examined the market and found that such a facility was not available, so we built new and additional dynamometer facilities here at Yoxhall. These have take three years to install and perfect.

This advance was made possible by our previous 20 years dynamometer experience, gained whilst leading the field in Healey engine design. This dyno has been called 'the most sophisticated in classic racing' and we know that it will enable us to develop the extra power that customers seek.

Capability

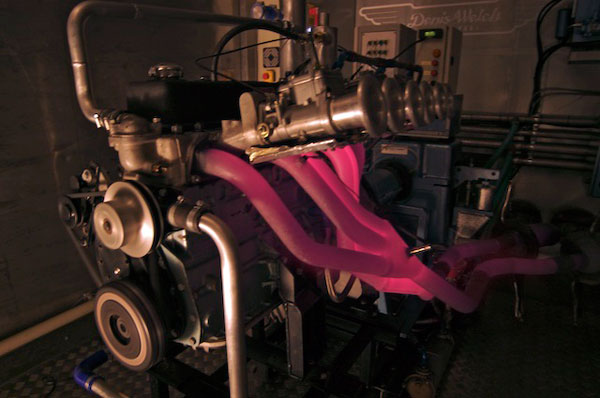

The high degree of flexibility built into this system and our simple 'make ready' jogs mean we are now able to cater for more exotic engines in other marques in a simple and effective manner.

- Modern or Classic

- Large or Small capacity engines

- Fuel Injection or Carburettor

- Engine Mapping

- Left, Right or Centre exhaust

The development of this impressive facility has been a continuous programme of assessment, procurement, bespoke engineering, installation and constant evolution. It was our specific aim not to compromise on flexibility or performance. We wanted to be able to run all manner of engines and to test them to their full potential.

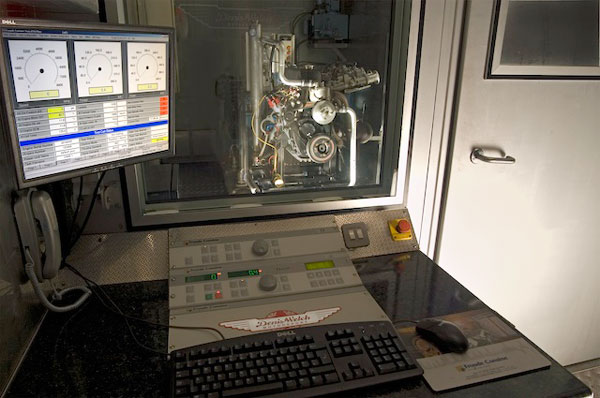

A purpose built, fly-by-wire controlled cell is now fully operational, sporting a barrage of sensors which provide us with a huge amount of information on the engine's performance.

Features include:

- Fly-by-wire throttle actuator

- Multi-mode digital control with bumpless mode transfer

- 32 Channels of signalling with 4 levels of alarming

- Manual and automatic test sequencing

- Data logging and test reports

- High accuracy of required RPM (typically +/- 2rpm)

- High accuracy control of water and oil temperature (typically +/- 5deg C)

- On-board starting system

- Quick change engine trolleys for reduced down time and workshop installations

- Moveable dyno positioning within the test cell to allow for radical exhaust layouts

- Flexible waster and oil layouts to allow for most installations

- Computer controlled variable speed cell fan

- Remote access for confidential private hire - fully self-contained

- Fully sound proofed.

Timely Advice

Customers often invite us to advise before they get involved with a particular car or type of competition. This enables use to user our vast competition knowledge to determine the choice of engine, cam, crank or gearbox etc. This often helps to ensure that vital consideration on cam timing, torque v bhp and drivability are resolved.

Please consult us before stripping your engine, the benefit of our experience could help you make your rebuild better still.

Development Consultancy

As an ongoing service for tjose interested in pushing the envelope even further we offer a consultance service for car development. This involves the very cutting edge technologies as used in other racing formulae, which is where our broad expericence in engine development and other race techniques become so useful. We can help to develop solutions to performance issues which can give that all important competitive advantage.