CNC Porting

Our new state-of-the-art 5 Axis Machining Centre, has enabled greater accuracy and consistency for products such as gas flowed cylinder heads and Manifolds.

After 17 years successfully producing our aluminium 100/4 cylinder heads we took the decision to upgrade our product. By reinvesting in modern techniques we continue to develop our products to be the best on the market, thereby staying ahead of the competition in so many ways.

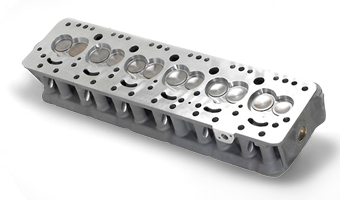

Cylinder heads

All are availalable in fast road and full race spec with matching inlet manifold to suit various carburettor sizes.

- Austin Healey 3000

- Austin Healey 100

- Austin Healey 100S

- Jaguar 3.8 & 4.2 6 cylinder Straight port

- Jaguar Wide Angle 6 cylinder

Inlet manifolds

- Austin Healey 3000 triple Weber, triple SU, twin SU

- Austin Healey 100 SU

- Austin Healey 100S Weber and SU

- Jaguar 3.8 & 4.2 6 cylinder Straight port triple Weber

- Jaguar Wide Angle 6 cylinder Triple Weber

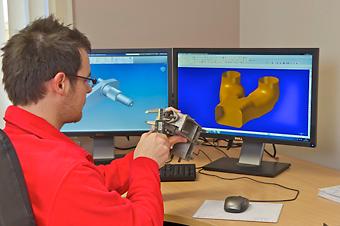

We have gone back to the drawing board and started with completely new CAD drawings to ensure accuracy and perfect detail in our product.

Increased investment in CAD software has allowed us to redraw the head in 3D as a solid model, producing all new technical drawings - including fully modelling and drawing the inlet and exhaust ports.

We have further enhanced this ‘design to manufacture’ investment philosophy by including state of the art CAM software. This has allowed us to plan the tool paths and write the machining program from a professionally designated drawing office, not the shop floor, linking these programs direct to the CNC machine, with a dedicated computer network.

Around 607,000 lines of code will download, just to machine the ports of a fast road 100/4 head with a continuous time of 5 hours and 20 minutes. When it comes to machining, the past two years have seen a huge upgrade to our capabilities with the acquisition of a brand new 5 Axis CNC Machining Centre.

This has allowed us to fully machine the inlet and exhaust ports along their entire length, which involves around 5 hours of continuous machining – so no more hand gas flowing like the old days with its inherent inconsistencies making each head liable to variations in flow capability - this is now eliminated. What we design is what you will get every time.

Benefits of our heads

- Fully CNC machined chambers

- CNC ported inlet manifolds match seamlessly

Now the ports are machined with symmetry and are all identical, not only from head to head but each port along an individual head. This makes for considerably higher power gains and balanced performance, with the potential for each engine to give much more consistent power outputs than ever before.

We not only lead the Austin Healey market with this technology, we are at the very front of modern engine development offering this service to all makes and types of engine.

So whether you require a standard, fast road or full race head, there really is no better or more up to date version available on the market today.

Be sure to buy a Denis Welch Motorsport original…look for our logo!